Regardless of the industry you're in, precision machined parts are crucial for delivering optimal performance. Manufacturing high-precision machined parts requires a wealth of skills, expertise, and advanced technology. There are many manufacturers that provide these components, but few like CFY. We are renowned for delivering high-quality components with precision manufacturing in the shortest turnaround time possible.

Sliding head CNC turn-mill machines are typically used to process small batches of complex parts using multiple cutting tools in a single setup. To provide specialized programming, optimization, and simulation tailored for these machines, combines comprehensive milling, turning, and measurement cycle packages, supporting specific components like sliding spindle mechanisms, guide bushings, turret-style tool holders and tool carriages, sub-spindles, and coaxial mechanisms.

With Sliding head turn-mill hybrid machining, all machining on the part can be completed in a single setup, even for parts that previously required multiple setups or multiple machines. Process optimization strategies include segmenting programs, utilizing guide bushing support for increased stability and more aggressive cutting action, and specialized cutting cycles (e.g., synchronous turning and synchronous milling) that enable the simultaneous use of multiple cutting tools in a single operation. Synchronous and overlapping motions are employed using machining modes to optimize the machining cycle time for the entire process.

Performance of precision machined parts depends on the type of material used. Each material possesses its own unique characteristics, and we have a deep understanding of them. At CFY, Inc., we offer precision machining services for the following categories of materials:

- Aluminum Alloys: In the past, we have provided precision machined parts made from aluminum alloys like 5052, 6061-T6, and 7075-T6.

- Alloy Steel: Our machining experts frequently handle the following alloy steel variants:

Low Carbon Alloy Steel: 16Mn, 4118, 16MnCr5, 8620, etc.

Medium Carbon Alloy Steel: 4340, 4140, etc.

Medium Carbon Alloy Steel: 4340, 4140, etc. - Stainless Steel: We have expertise in the following grades of stainless steel:

Austenitic Stainless Steel: 303, 304, and 316

Precipitation Hardening Stainless Steel: 17-4 PH, 15-5, etc.

Stainless Steel: 440C, 420, and 410 - Tool Steel: We work with various tool steels such as CVM-350, CPMV series, D2, A2, S7, O1, W1, etc.

- Brass: We manufacture various precision parts using brass CDA 360/385.

- Nickel: Our specialists can produce parts using nickel CDA 798 NM2 and CDA 793 N12.

- Other Materials: Apart from the aforementioned materials, we also work with the following:

Beryllium Copper

Polyoxymethylene Resin Polyether Ether Ketone

Tellurium Copper

Aluminum

Titanium

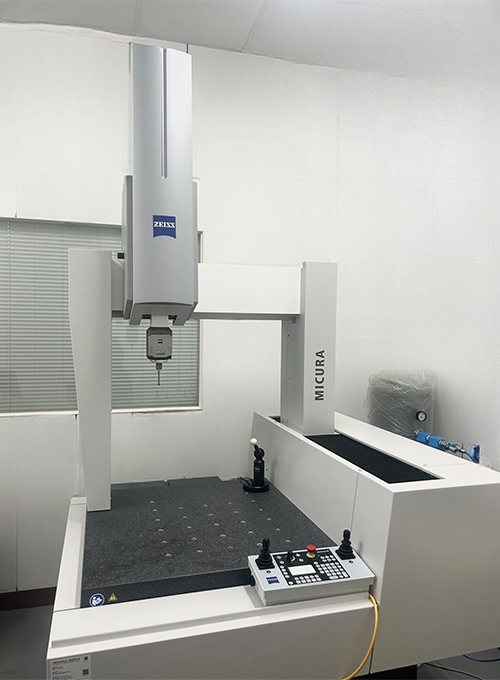

New Testing equipment

ZEISS MICURA

Lab Grade Accuracy

Small Footprint

Ceramic Construction

Highly Precise Component Measurement Solutions with Impeccable Accuracy

No matter the size of your business needs in high-precision component measurement, we boast the most advanced technology and professional expertise to ensure you receive precise and reliable results. Our measurement systems combine state-of-the-art inspection equipment with highly trained technical personnel to ensure that every measurement task meets the highest standards.

What sets us apart?

- Advanced Technology: We utilize the latest high-precision measurement instruments and techniques to ensure the accuracy and reliability of measurement results.

- Professional Team: Our technical personnel have extensive experience and professional knowledge to tackle various challenges and provide the best measurement solutions.

- Professional Team: Our technical personnel have extensive experience and professional knowledge to tackle various challenges and provide the best measurement solutions.

- On-Time Delivery: We are renowned for our efficiency and on-time delivery, ensuring your projects are completed on schedule and meet your timelines.

Our service scope includes but is not limited to:

- Precision measurement of small to large components

- High-precision surface morphology analysis

- Material structure performance testing

- Other customized high-precision measurement services

No matter how complex or challenging your measurement needs are, we have the capability to provide the best solutions. Contact us to learn more about our services and how we can meet your high-precision component measurement requirements