With vertical milling, a 3-axis milling table is the work surface, which sits below the arm, to which a spindle is attached.

The spindle can be stationary if a turret vertical mill is used. In this case, the table moved along both X and Y axes.

Meanwhile, the table only moves along the X-axis if a bed vertical mill is used. The spindle travels along the length of the arm in the Y-axis direction.

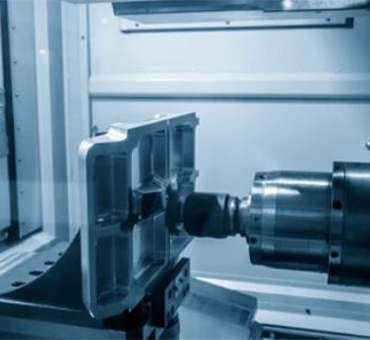

With horizontal milling, the spindle operates horizontally instead of vertically, and all other horizontal CNC milling machine components are similar to vertical milling.

Generally speaking, horizontal mills are best suited to heavier projects or longer projects. They are also suited to parts that require a large amount of material to be removed as the swarf falls away from the part and cutter.

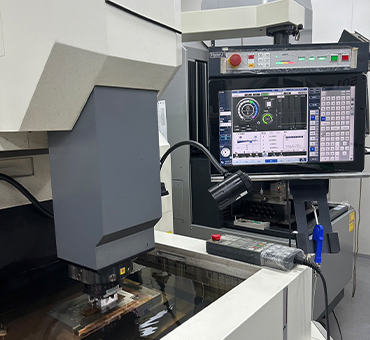

Precision electrical discharge machining is a high-precision manufacturing technique commonly employed for producing components with intricate shapes and demanding precision requirements. This method primarily utilizes the principles of electrical discharge, where sparks are generated on the surface of the workpiece to remove material, achieving the desired shape and dimensions.

Precision wire cutting machining is an advanced manufacturing technique primarily applied to the production of complex-shaped, high-precision metal components. This technology utilizes the principle of high-energy electrical spark discharge to precisely control the metal wire cutting process, creating components that meet design specifications.

One of the advantages of precision wire cutting machining is its high manufacturing accuracy, capable of achieving micrometer-level cutting precision. This makes it an ideal choice for manufacturing intricate parts, molds, and other products that require high precision. Additionally, this machining method can handle a variety of metal materials, including stainless steel, aluminum alloys, and titanium alloys.

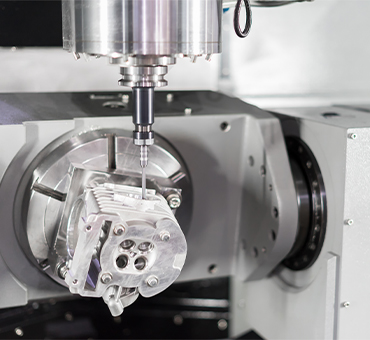

The term 5-axis machining refers to a type of multiaxis subtractive manufacturing in which the machine that cuts away stock material can move in five axes. In machining, the number of axes a machine uses determines the different directions either its tool or its table can move. There are three basic axes that any CNC milling machine uses: X, Y, and Z; or left-right, towards-away, and up-down. A 3-axis machine can use only these three linear axes. A 5-axis machine, however, can use two additional axes: A and B. The A-axis describes movement (or rotation) around the X-axis, while the B-axis refers to movement around the Y-axis.

Form milling is best used for milling operations where more irregular surfaces are involved. Contours, outlines, edges, or parts with curved, flat surfaces.

It employed milling cutters or fly cutters specialized for particular applications – for example, concave cutters or corner rounding cutters. Hemispherical or semi-circular designs or other similarly intricate designs with complex parts would benefit from the form milling technique.

CFY is a professional CNC service manufacturer specializing in the production of precision metal stamping, Ti-6Al-4V alloy parts, joint replacement parts. We focus on cnc metal stamping of small, complex precision stamped components, boasting a team of engineers with 14 years of stamping experience. From prototype to production, our team can provide you with the optimal CNC machining solutions. In our time helping clients with creating products and parts we've seen and done it all. Experience & expertise is important when it comes to manufacturing products.

Titanium alloys exhibit numerous unique properties, making them often the optimal choice for CNC machined parts with special applications. Titanium boasts an impressive strength-to-weight ratio, being 40% lighter than steel while retaining only 5% less strength. This makes it exceptionally well-suited for high-tech industries such as aerospace, automotive, medical technology, and energy. The titanium machining process involves milling the metal raw material into the desired parts or components.

Chien Feng Yuan specialize in CNC turning, CNC milling, CNC grinding, aluminum machining service and have successfully collaborated with companies in these field. We are also a cnc stainless parts maker with over 14 years’ experience on this field which give us tremendous depth, experience & knowledge about molding. In our time helping clients with creating products and parts we've seen and done it all. Experience & expertise is important when it comes to manufacturing products.