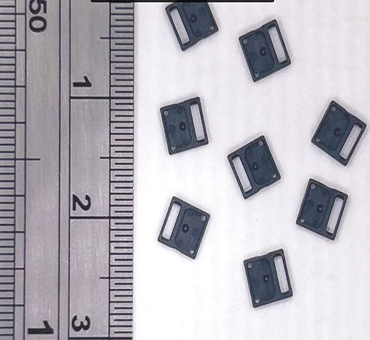

Injection molding has been used to make larger and larger components in recent years. Think of big screen TVs, automotive panels, and large-scale equipment. While injection molding is getting larger, it’s also gone in the opposite direction. Micro injection molding is being used to create smaller and smaller products. As smart devices have decreased in size, they have required smaller components at an economical price. The medical industry is also utilizing micro injection molding to create smaller surgical tools and medical devices, and the military is using smaller components with technological advances. Quality control over these small components has been kept very high with specialized inspection methods, and it looks to be a promising trend in the future.

Like general injection molding, double-shot molding requires the material to be melted at a high temperature in the filling tank, and then injected into the mold through the internal screw for shaping. The feature of two double-shot molding is that it can produce two different materials at one time. The common technology is to inject a relatively hard rubber or plastic housing first, and then move it to another mold immediately, and inject a soft elastomer to coat it, which is called two shot molding. The steps sound simple, but it is not easy to complete. It needs to be equipped with a dedicated machine and more complex molds to achieve. Although the initial investment cost of double-shot injection molding is higher than that of injection molding, the benefits and features of two shot molding can bring greater profits to the market.

Insert molding is a versatile process that provides numerous benefits, making it a preferred choice for the production of complex and integrated components in various industries.

CFY specialize in plastic injection, plastic injection, Injection Molding and Parts, thermoplastic injection molding and have successfully collaborated with companies in these field. We have over 14 years’ experience on this field which give us tremendous depth, experience & knowledge about molding. In our time helping clients with creating products and parts we've seen and done it all. Experience & expertise is important when it comes to manufacturing products.

CFY specialize in design injection molded plastic parts, injection molding automotive parts, injection mold and have successfully collaborated with companies in these field. We have over 14 years’ experience on this field which give us tremendous depth, experience & knowledge about molding. In our time helping clients with creating products and parts we've seen and done it all. Experience & expertise is important when it comes to manufacturing products.

Many industries can benefit from incorporating plastic gears/precision gear molded components into their design. Chien Feng Yuan excels in designing, engineering, and manufacturing precision plastic gears for various industrial applications. They utilize advanced technologies and materials to produce gears with superior performance, durability, and reliability. Their extensive product range includes spur gears, helical gears, bevel gears, worm gears, planetary gears, and more, with all products manufactured with meticulous attention to detail and precision.