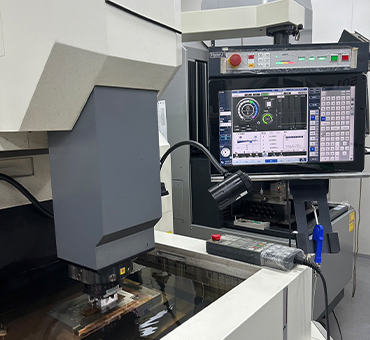

One of the key advantages of precision electrical discharge machining is its capability to handle high-hardness and difficult-to-machine materials, such as hard alloys, titanium alloys, and high-speed steel. This machining approach does not require direct contact with the workpiece, thereby avoiding the introduction of mechanical stress to the material and contributing to the maintenance of the component's precision and surface quality.

During precision electrical discharge machining, operators can adjust discharge parameters according to design specifications, ensuring the production of components that meet the requirements for precision and surface smoothness. This flexibility makes precision electrical discharge machining an ideal choice for manufacturing molds, tools, and other high-precision components.

In summary, precision electrical discharge machining provides a reliable solution for manufacturing high-precision components through precise control and highly adjustable parameters. It addresses challenges related to materials and shapes that traditional machining methods find difficult to handle.

Mirror Electrical Discharge Machining is a highly precise manufacturing technique focused on creating components with a mirror-like glossy surface. This method primarily employs the principles of electrical discharge, inducing tiny electrical sparks on the workpiece's surface to precisely remove material, achieving the desired surface smoothness and shape.

The distinctive feature of Mirror Electrical Discharge Machining lies in its pursuit of ultimate surface quality, capable of producing parts with an exceptionally smooth and reflective finish. This technology finds widespread application in the manufacture of high-end optical components, precision molds, and other applications where stringent requirements for surface perfection exist.

One of the advantages of this machining method is its ability to handle a variety of challenging materials, including high-hardness alloys and other specialty alloys. Mirror Electrical Discharge Machining, as it does not require direct contact with the workpiece, helps avoid introducing mechanical stress, contributing to ensuring the precision and surface quality of the components.

During Mirror Electrical Discharge Machining, operators can finely adjust discharge parameters to ensure compliance with design requirements, producing parts with extremely high surface flatness. This high level of controllability makes Mirror Electrical Discharge Machining an ideal choice for manufacturing precision optical systems and other components with high demands on optical performance.

In summary, Mirror Electrical Discharge Machining provides an outstanding solution for manufacturing products with extremely high surface smoothness, thanks to its exceptional surface treatment capabilities.